This training is for Prusa printers; if you are looking for Ultimaker printers, you can find that here.

If you want to train yourself on an FDM 3D Printer, you will need to have a thorough understanding of what is covered in this user guide. A staff member can give you a credential allowing you to use an FDM 3D printer independently if you can demonstrate an understanding of the 3D printing process. This includes:

- A walkthrough of how you would set up a printer on PrusaSlicer, including a brief explanation of the core settings (I.e. walls, infill, materials)

- What are some safety precautions you should take when operating a 3D printer?

- What is the anatomy of a 3D printer?

This document will walk you through the basics of FDM printing. Text in black explains certain concepts.

Text inside blue boxes are steps you should actively take to guide you through this process.

What is an FDM 3D Printer?

FDM stands for “fused deposition modeling”. An FDM printer melts plastic and extrudes it in a pattern—basically, depositing layers of fused plastic to make a 3D model. The pattern is determined by a digital 3D model, which a printing software will “slice” into layers.

Safety Considerations

EXP Makerspace 3D Printing Policies

- FDM Printers are free to use.

- Stay around to watch the first few layers of your print, as most prints fail early on. If we notice a print started and you are not there, we will stop your print for you and you will not get notified that we’ve stopped it.

- The laundry machine model:

- If you are not here to pick up your print when it’s done, someone may move it for you and start their own print job (just like if you don’t pick your clothes out of a washing machine, the next person can remove your clothes and run their own laundry).

- If you remove someone’s print to put your own on, please put it in the corresponding blue bin. Each printer has its own bin. Write down the previous patron’s contact info on the card in front of the bin.

- Card access:

- Upon completion of the FDM printer DIY training OR the SLA printing training, you will get card access to the 3D printer room. Wait a few days for it to update.

Advanced credential policies:

- Upon completion of the Advanced 3D Printing canvas quiz, you may bring your own filament for the Prusas. You may use any Prusa machine you’d like.

- Explorers will load/unload filament for you. Patrons cannot change out filament.

- The makerspace is not responsible for other people using your filament. Get an Explorer to remove it for you when your print is done.

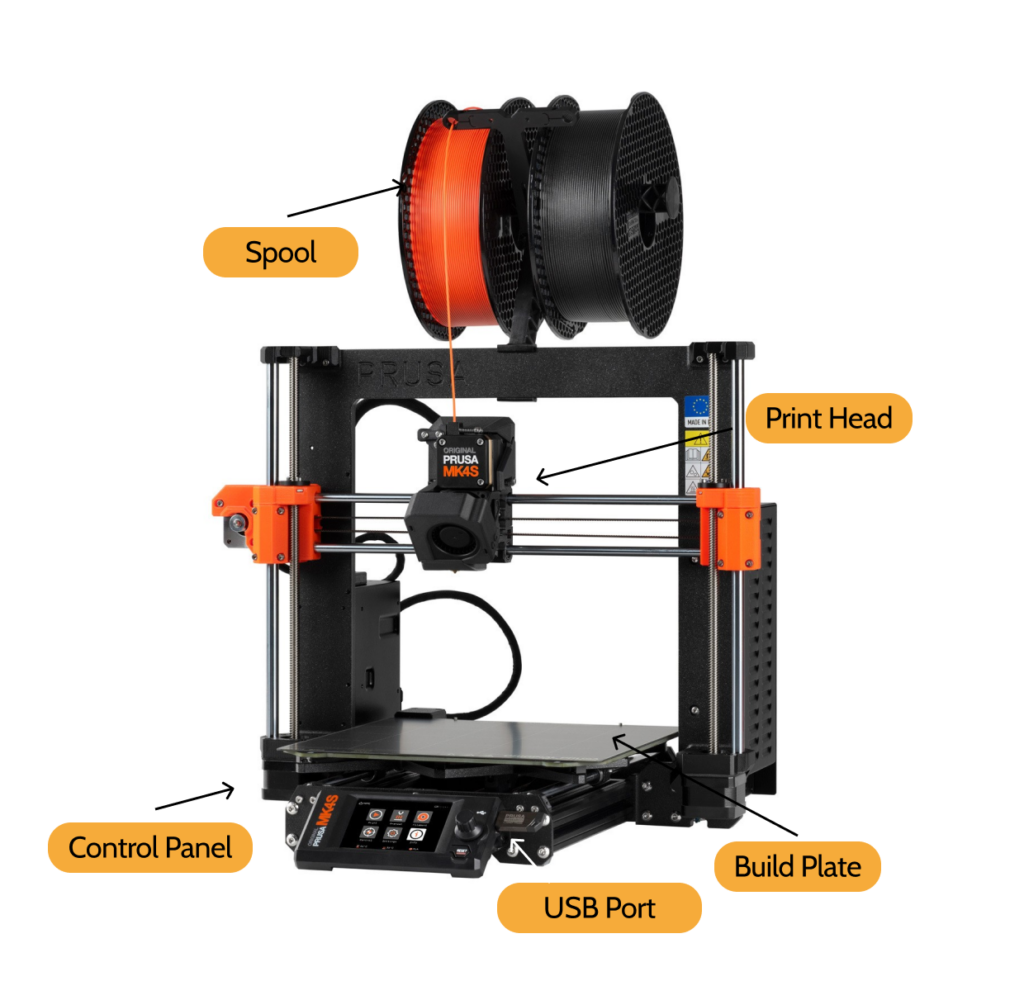

Printer Anatomy

The printers we use are Prusa mk4s. They have a build volume of 250 x 210 x 220 mm (9.84 x 8.2 x 8.6 in).

Downloading Software + STLs

PrusaSlicer, the free slicer software for Prusa machines, can be downloaded here. In this training, we’ll be learning how to 3D print with Benchy. Benchy is a popular 3D print testing file, since it’s small and has enough detail and overhanging parts to demonstrate what works best for your print settings.

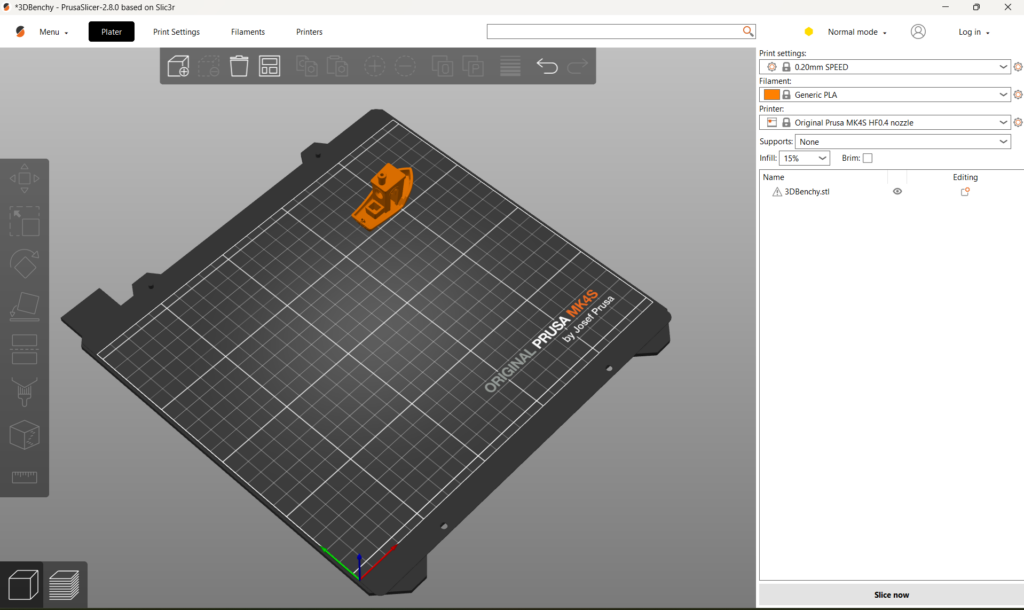

Load your part into Prusa Slicer

- Download PrusaSlicer (it’s free!) and open up the software.

- Download Benchy here. The STL file we’ll be using is titled “3DBenchy.stl”.

- Click the “Open File” icon in the top left corner. Select the STL file you want to print and open it

- Your part will appear in the Prusa workspace window. If it fits in the printer workspace, it will appear orange. Otherwise, it will appear blue, which is too big to fit in the printer.

- Click the orange model to bring up the placement menu on the left side. Use the top two buttons to adjust your piece:

- Move will let you reposition your piece.

- Scale will change the size of your piece. If you are making a functional rather than a decorative piece, be careful: this will also resize things like bolt holes.

- The other buttons won’t be used here, but they are helpful to know:

- Rotate will change your piece’s angle, which is the most important placement setting to get right. Rotate your piece, so it sits securely, and won’t need too many or too tall supports.

- Place on face will place a face of the part directly onto the print bed.

- Paint On Supports can be painted on in certain parts that you believe that you need supports– think overhanging pieces or delicate details.

- Seam painting can help with the seams that happen when each layer completes and the print head moves up. The process of moving up the print head for each layer can sometimes cause a seam, or a scar, up the side of your part.

Try out the above buttons to perform the following actions:

- Move the piece to the top right corner of the print bed.

- Scale it down by .75x.

Select print settings

- Material: Select the material you’re using. At the makerspace, we only stock PLA, as it’s a good “all around” printing material that has higher success rates than other materials. We do not stock ABS, which is a stronger material than PLA; this is because the melting of styrene (the “S” in ABS) off-gasses noxious fumes that make many people ill.

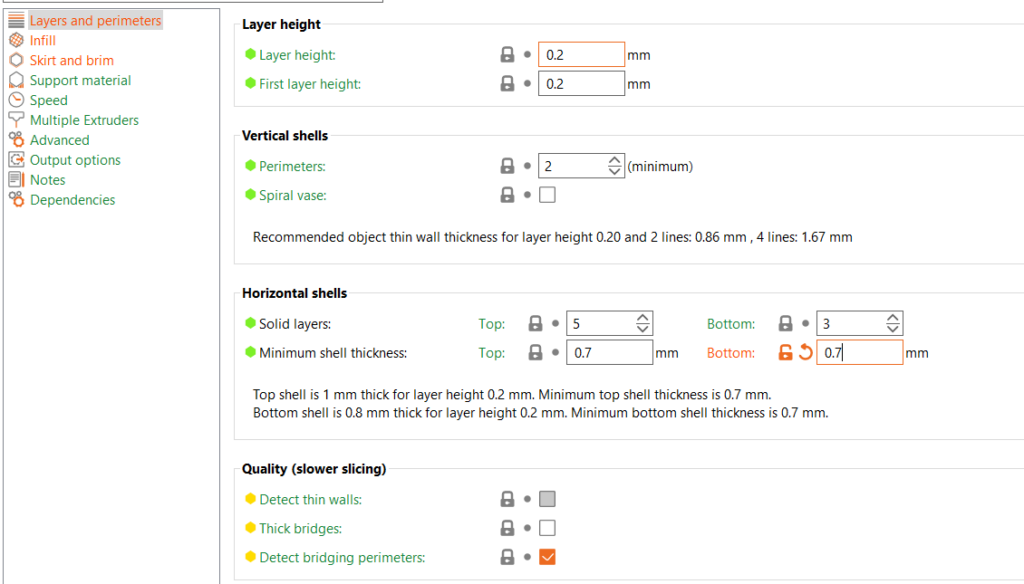

- Resolution is how thick the slices are. Smaller layers will mean the print is of higher quality, but it will also take longer since there will be more layers. A good layer height is 0.25 mm.

- Shell thickness is the outside of the piece. Printed parts are semi-hollow, but the shell is solid up to a small depth. A suitable wall thickness is 0.6 mm, strong and thick enough for scratches. If you are printing something that needs to support a lot of weight, you can turn the wall thickness up to 1 mm.

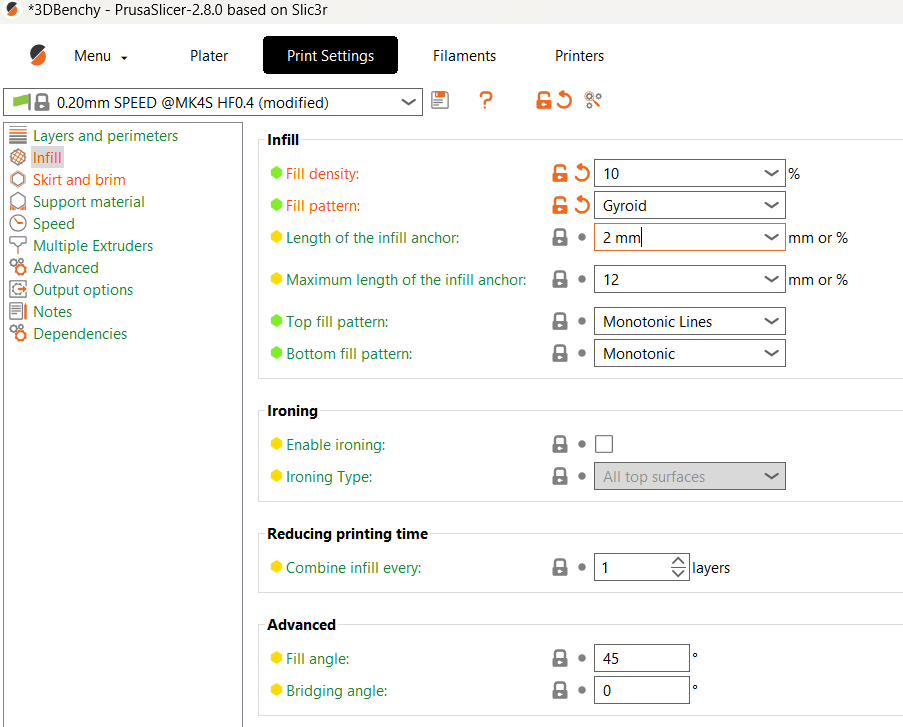

- Infill is the inside of a 3D-printed part. Typically, it’s filled with a honeycomb pattern, but this can be changed depending on application, as some patterns provide strength in different directions. You can change infill density as well, and 20% infill is a good number. Even as low as 10%, a piece will still be strong. 30% is very high and should only be used on pieces that need to support a lot of force. Higher infills will extend the print time and use more filament, so don’t make it higher than you have to.

- Supports are printed scaffolding that supports any overhanging or curved parts of your piece to prevent it from collapsing. Supports are made to break away easily, so you can remove them after you print.

- Best practices for supports: While supports do break off easily, you shouldn’t have supports on important features of your project (parts requiring highly precise dimensions, the most aesthetically critical parts of your print, etc). This is because the supports will slightly warp whatever they’re attached to and could also chip your part when you remove them. While of course you can sand away imperfections, that might mess up any important features.

- Build Plate Adhesion determines what prints where your piece sits on the build plate. There are four options: None, Skirt, Brim, and Raft.

- None means the printer will start with your piece without making a base, which is risky, as prints are more reliable with a base.

- A Skirt is a thin line of filament that outlines your piece but doesn’t touch it. This is almost the same as None, but it gives the extruder a chance to warm up first, making it slightly less likely to jam.

- A Brim is a thin sheet printed beneath your part. A brim helps your piece adhere to the build plate, holds the bottom flat during the early stages of the print when the piece is thin, and gives the piece protection against scratches when you remove the piece from the printer. Brims are usually the best option.

- A Raft is a much thicker version of a brim, and it serves the same benefits but is much better at preventing warping. It has the downside of increasing the print time and using extra filament, so it should only be used when warping is a concern.

Set up your part so it has the following settings:

- PLA

- .2mm layer thickness (under SPEED)

- .7 shell thickness

- Gyroid infill pattern with 10% infill

- Support turned off

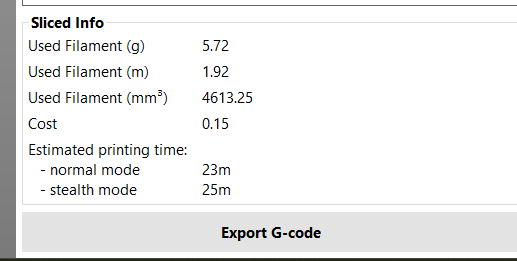

Once your settings are ready, click “slice” in the bottom right corner. This will generate a “gcode” of your part – instructions for the printer. It will also tell you how long your print will take, how many grams of material it will use, and how many meters of filament it will use up.

- Your part should take 23 minutes, weigh 5.72 grams, and use 1.29m of filament.

Operating the Printers

Printer Check-up

- Check if the bed is clean. If any old prints are left there, remove them and put them on the shelf. If scrap bits of filament are on the bed, gently wipe them off with your hand or a paper towel.

- Make sure the nozzle is clean. If plastic is solidified on it, gently pluck it off by pulling it downwards.

Load part into the Prusa printer itself

- Once the file is set up in PrusaSlicer and the printer is ready, you can start the print.

- Since you’ve already sliced the part, you will see a button that says “Export G-code.” With a USB drive in the computer, click this to save your gcode to the drive. Safely eject the drive and plug it into the front of the printer.

- Using the dial on the Prusa, go to “Print.” Then scroll through to find your piece, select it, and hit print. Your part will start to print automatically.

While your part is printing

- Part of the beauty of 3D printing is that after setup, the machines are completely automated. You don’t need to stick around for the whole process, but you need to watch the first few minutes.

- The printer will heat the bed and the nozzle, which will take a minute or so. Then it will move to the front left corner and extrude a small blob of filament. This is to ensure the machine extrudes properly – if you don’t see a blob, pause the print and ask an Explorer to help you fix the filament.

- The vast majority of 3D printing failures happen during the first few layers. Watch the printer make the brim or raft, and let it print enough to be sure it’s working. If something goes wrong, stop the print and ask an Explorer to help you fix it.

Retrieving your part

- Make sure you know how long your print will take and when it will be done. Try to come back and get it soon after it is ready. This saves the next person the trouble of removing your part from the bed and avoids the risk that someone will mishandle it.

- Use common sense here. If a part is going to be done at 3 am, you don’t have to get it then – sometime the next day is fine.

When you retrieve your part, you can remove it from the bed using one of the scrapers hanging on the wall. It’s better to use the scraper like a chisel, removing the piece with several tiny pushes rather than hacking it off all at once. More forceful pushes can scratch and damage the bed.

CAUTION: Never push the tool in the direction of your hand. This is one of the most common 3D printing injuries!

Congratulations! Now that you have finished your print, you can bring it to the front desk and get the credential!