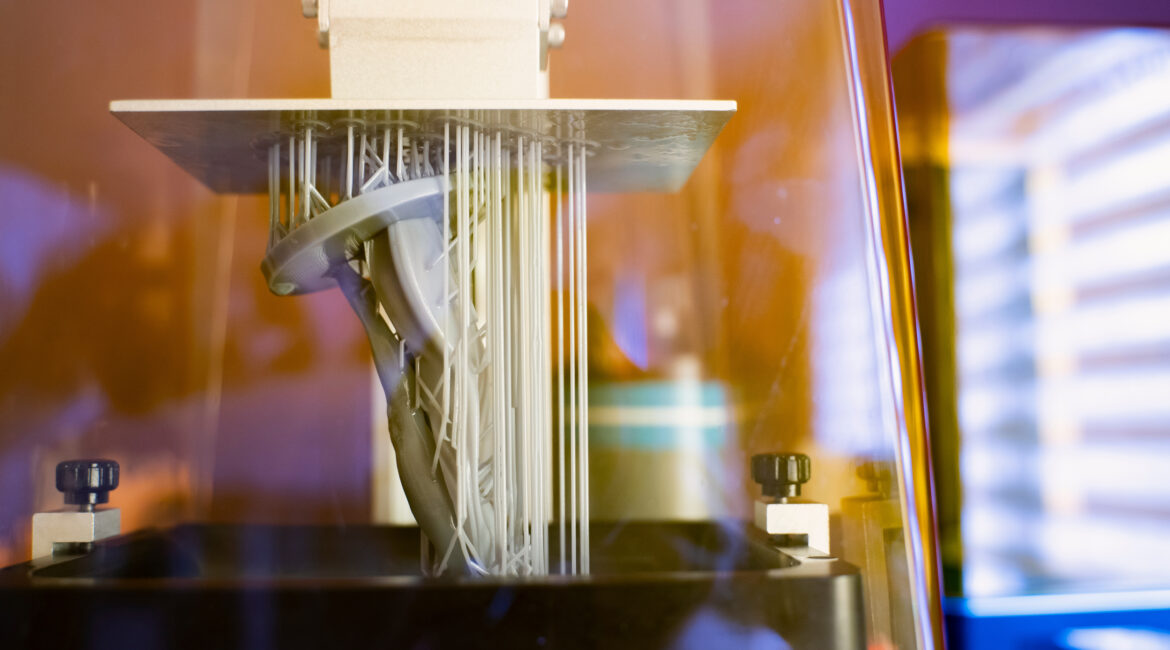

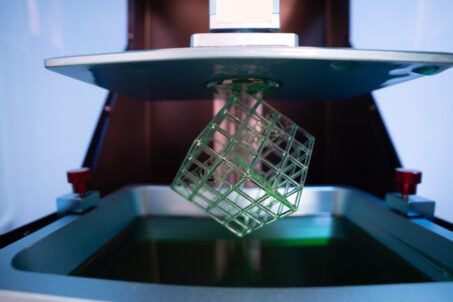

An SLA 3D printer, or a stereolithography apparatus printer, utilizes light-sensitive resin to print 3D files. An ultra-violet laser shines through the resin while the print bed moves upwards, printing out files a layer at a time. This allows the printer to make incredibly detailed prints, with some printers and materials having up to 25 microns (.025mm!) in layer thickness. Training for SLA printing will include setting up prints and post-processing them, which is a process that includes a wash in isopropyl alcohol and curing in an ultra-violet oven. When printing with SLA, plan for at least another hour to accomodate for post-processing.

Models at EXP

Formlabs 3L (x2): has a build volume of 33.5 × 20.0 × 30 cm.