If you want to train yourself on the horizontal bandsaw, you will need to have a thorough understanding of what is covered in this user guide. A staff member can give you a credential allowing you to use the horizontal bandsaw independently if you can demonstrate an understanding of the process. This includes:

- Clamping your piece and cutting it safely

- Understanding how the arm speed relates to the material that you are cutting

This document will walk you through the basics of the horizontal bandsaw. Text in black explains certain concepts.

Text inside blue boxes are steps you should actively take to guide you through this process.

What is a horizontal bandsaw?

A horizontal band saw is a power tool with a continuous, toothed band blade that moves parallel to the ground. It is used for cutting long stock and making straight cuts by holding the workpiece stationary and while the arm carrying the blade lowers down.

Safety Considerations

Horizontal Bandsaw Policies

You may not cut down stock that is smaller than five inches.This is because it cannot be clamped properly inside of the machine.

Horizontal Bandsaw Anatomy

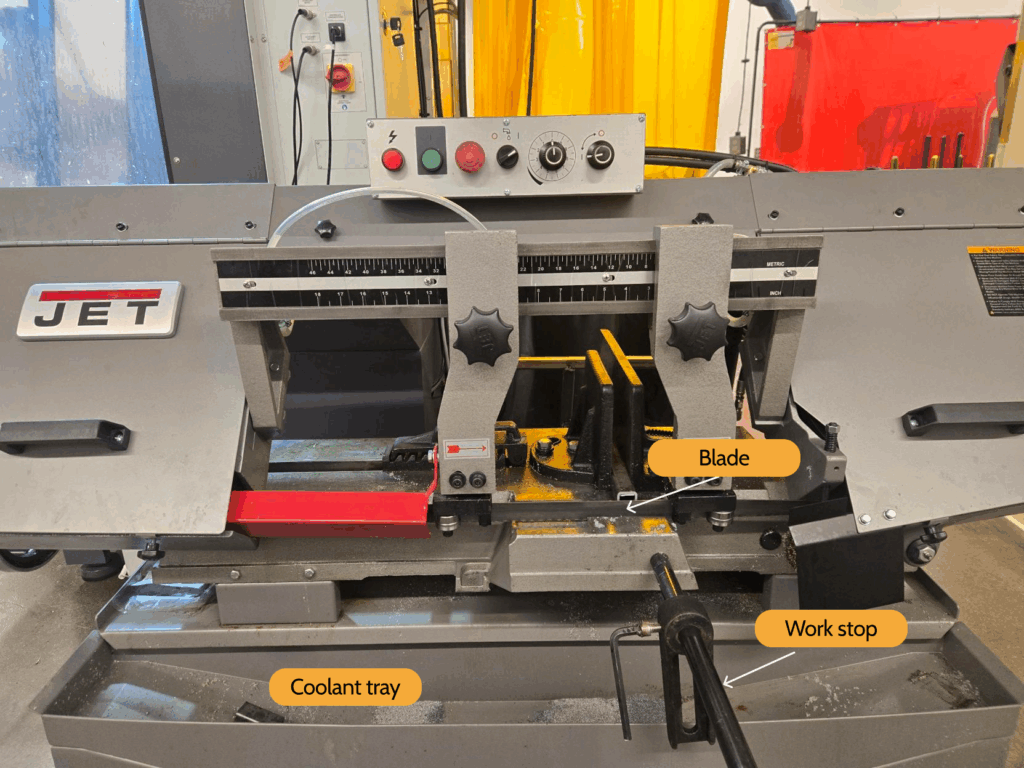

- Blade: This blade is a full band, but only a small part will be exposed, which is the part that will cut your stock. It rotates at a constant speed and tension.

- Coolant tray: This is where coolant and metal chips get collected.

- Work stop: If you want to cut the same length of metal, you can just the metal piece on the rod that comes out of the bandsaw. Tighten with the allen key handle.

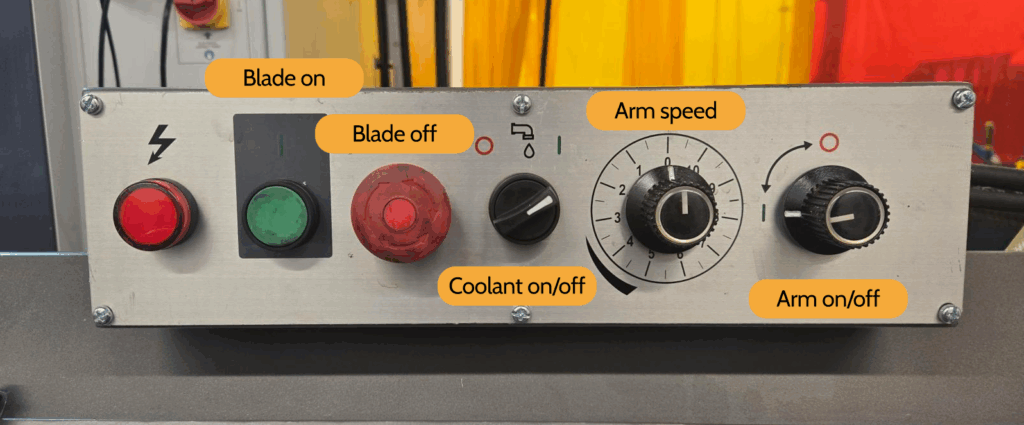

- Blade on: Pressing this turns the blade and coolant pump on.

- Blade off: This turns the blade and the coolant pump off. Twist this to disengage.

- Arm speed: Controls the downward speed of arm. 10 is the fastest, 0 is unmoving.

- Coolant on/off: The green line means that when the blade is on, your coolant will run.

- Arm on/off: When switched to the green line, the arm will move down. When switched to the red circle, the arm will stay nonmoving.

How to use

- Install your piece in the vice:

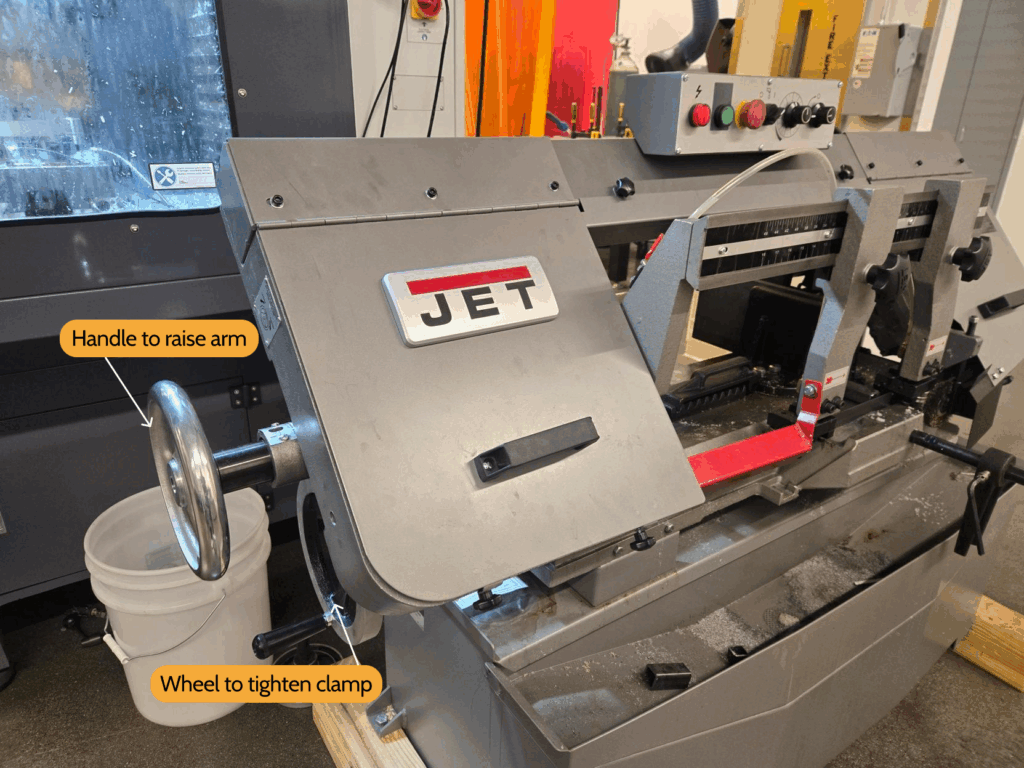

- Raise the arm up, load your piece into the clamp, and tighten down with the wheel.

- If you would like to cut on an angle, you can adjust the two screws circled in orange with a wrench.

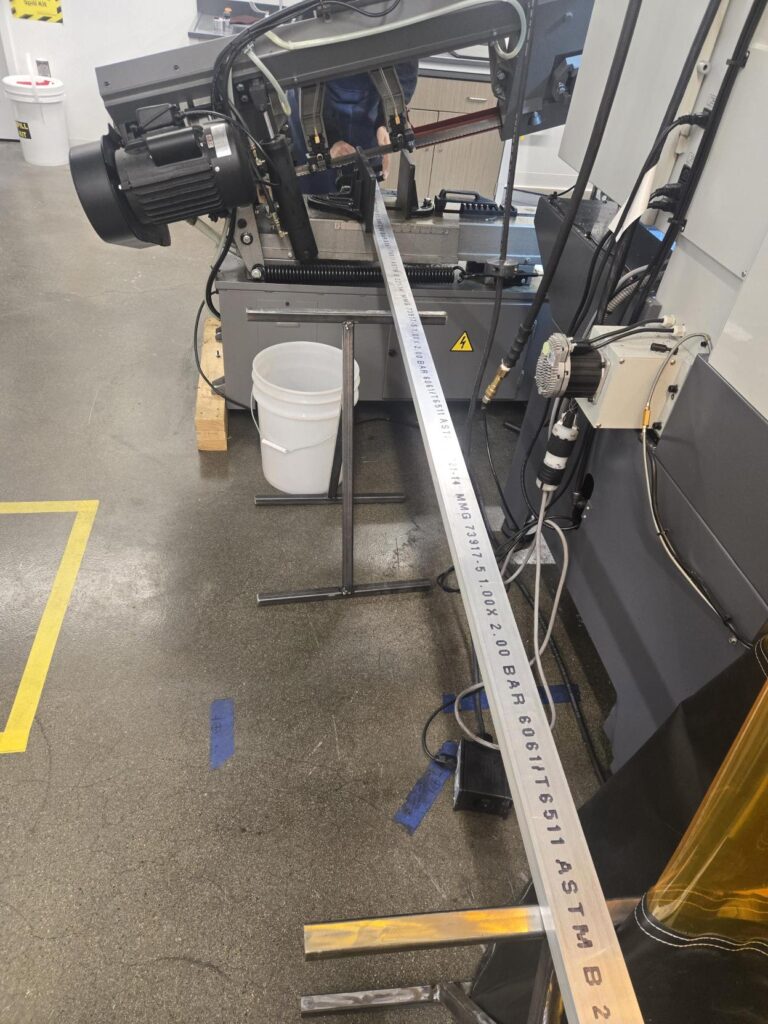

- If your piece is very long and sticks out of the back of the bandsaw, you can use the two work stands located behind the bandsaw.

- If you would like to cut multiples of the same length of bar stock, use the work stop to align your stock. Tighten the work stop with the lever on it.

- Lower the arm until the blade is about an inch over the piece, using the arm speed dial and with the arm turned on.

- To see if your piece will be cut, stand above your piece. It is important to note that this is meant for rough cuts only– your piece will not cut very precisely!

- To see if your piece will be cut, stand above your piece. It is important to note that this is meant for rough cuts only– your piece will not cut very precisely!

- Turn the blade on by disengaging (twisting) the red “blade off” button and pressing the green “blade on” button.

- If you are cutting metals, make sure the coolant is running by turning the coolant switch to the green “on” side.

- Coolant does not need to be on for cutting plastics.

- Use the arm speed dial to lower the arm while the blade is running, which will cut your stock.

- If you are cutting steels, go between 2.5 and 3.5 for speed.

- If you are cutting aluminum, go between 3.5 and 4.5 for speed.

- Do NOT touch your stock while the blade is running. The blade and coolant pump will turn off as soon as the arm completely lowers.

- If the bandsaw stalls and stops lowering into the part, use the arm handle to bring the arm up while it is still running, and cut again. This may happen if you are going faster than our recommended settings.

- To clean up, return all stock to where you found it.

- Coolant: You may NOT wash parts with coolant down the drain, since Massachusetts law prohibits dumping of chemicals (like coolant) down our drain. Use a paper towel to dry your part. If you wish to wash your parts off, you can use the hose attached to the waterjet and rinse them off in the waterjet.

- Burrs: Beware of any burrs left behind! Burrs are the raised edges of the stock that may get left behind from cutting. Use a deburring tool to remove any burrs. Never run your fingers parallel to the cut edge– that is how you slice your fingers.

Using the steps above, cut a 5.5″ piece of 1×2 aluminum bar stock. These are the pieces that we use for CNC Mill training. If you need help carrying the bar stock, please ask for help! If your piece is especially long, you may need to use the outfeed tables (see below). You must ask a supervisor to supervise you while you cut this out. When you’ve cut it successfully, give your piece to the supervisor and they will mark you off as being ready to use the horizontal bandsaw independently!