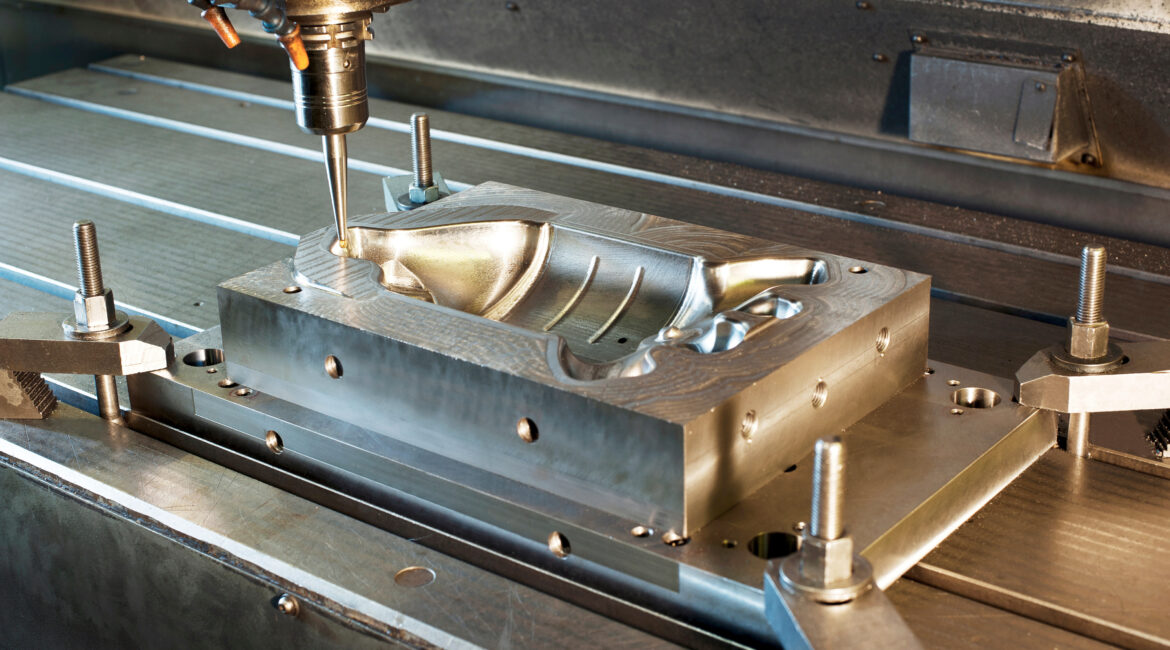

CNC’ stands for ‘Computer Numeric Control’, and a CNC mill is a subtractive manufacturing machine that cuts metal and plastics in three axes–X, Y, and Z–using computerized control. A CNC machine runs on G-code, which is produced by CAM (Computer Aided Manufacturing) software. Some CNC machines can be relatively easy to setup and use, though machining and designing for manufacture is a skill that can take years to acquire. Check in with makerspace staff who have machining listed as a specialty to review your design and make sure it’s machinable. Plan for extra time for your machining project! Machining is more work intensive process (and some would argue more rewarding…) than some other fabrication processes.

Models at EXP

Tormach 1100MX: X-axis travel: 18″, Y-axis travel: 11″, Z-axis travel: 16.25″

4th axis rotator.

Materials: aluminum, mild steel, most plastics